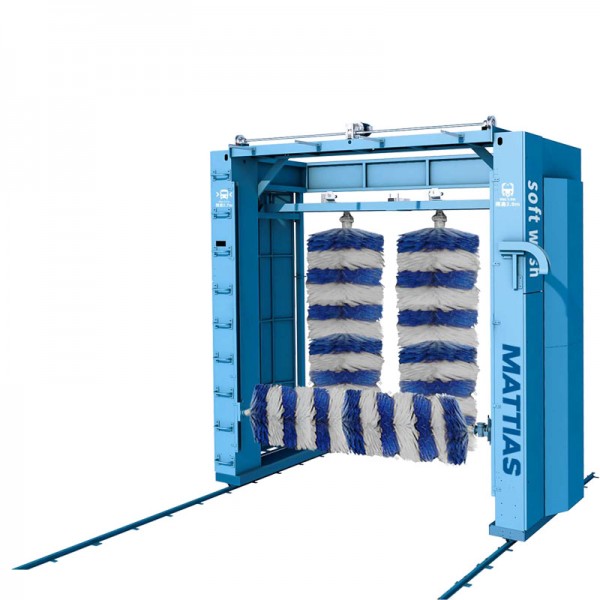

M-BS0500G Drive Through Bus Wash Systems

Login or create an account

CloseReturning Customer

I am a returning customer

Login or create an account

CloseRegister Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Thank you for registering with Balance Group!

You will be notified by e-mail once your account has been activated by the store owner.

If you have ANY questions about the operation of this online shop, please contact the store owner.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

M-BS0500G Drive Through Bus Wash Systems

Applicable car types: Buses, coaches, large passenger vehicles.

The M-BS0500G offers unbeatable efficiency and versatility for any commercial fleet operation. With the ability to wash up to 60 buses per hour, this machine is perfect for high-traffic bus stations, transportation companies, and cleaning services. Its durable design, powerful cleaning system, and optional unmanned operation ensure that you get the job done faster and with less labor. The optional intelligent low-temperature system also makes it a great choice for cold-weather regions. Designed to handle years of tough work, this machine is an investment in quality and productivity.

| Applicable Car Types | Bus, Coach, and Large Passenger Vehicle |

|---|---|

| Installation Space | 10 x 7.6 x 5.5 m(L*W*H) |

| Max.Washable Car Dimensions | unlimited x 2.8 x 3.5-4.2 m(L*W*H) |

| Car Wash Mode | Standard wash |

| Washing Mode | Drive-through foam+brushing |

| Estimated Wash Time | 40-60 cars/h |

| Estimated Power Consumption | 0.24 kWh/car |

| Estimated Water Consumption | 120 l/car |

| Estimated Wash Liquid Consumption | 50 ml/car |

| Rated Power (including air/dryer/water pump) | 9.95 kW ( without dryer) |

| Rated Voltage | 3-ph AC380V 50Hz |

| Air Source Requirement | 0.6~0.8 Mpa |

Applicable car types: Buses, coaches, large passenger vehicles.

The M-BS0500G Bus Wash Machine is designed for high-performance, offering an automated solution that can clean up to 60 buses per hour with ease. Ideal for large fleets, bus stations, or vehicle washing services, this machine provides unmatched efficiency and reliability in a tough, outdoor-friendly design.

Equipped with high-pressure stainless steel nozzles, the M-BS0500G removes dirt, grime, and road debris quickly and effectively. The precision-engineered proportioning pump from Germany ensures perfect detergent distribution, while the Italian motor guarantees lasting power and efficiency. Whether you choose the 3, 5, or 7-brush configuration, the machine adapts to meet your cleaning requirements.

For added convenience, the optional unmanned system allows for fully automated operation, freeing up staff to focus on other tasks. Additionally, if you’re located in cold climates, the optional intelligent low-temperature start-stop system ensures optimal performance even in sub-zero conditions.

Built with a hot-dip galvanized and powder-coated frame, this machine is engineered to withstand harsh weather and heavy use, offering years of reliable service and superior cleaning results.

Features:

1. The number of brushes is optional (3 to 7 brushes); Different brush types can be combined. Satisfy various requirements;

2. The number of cars washed is 40-60 car/h, meeting the needs of various scales;

3. Rear-view mirror protection;

4. Hot-dip galvanized and powder-coated frame;

5. Unmanned system (optional);

6. Stainless steel nozzle + high-pressure water , obvious cleaning effect;

7. A proportioning pump from Germany makes the lotion proportioning more accurate and reasonable;

8. Motor from Italy, makes the machine performance more stable and prolongs the service life.

Benefits of M-BS0400G Bus Wash Machine

- Washing Capacity: 40-60 buses per hour

- Brush Options: 3 to 7 brushes for customizable cleaning intensity

- Frame: Hot-dip galvanized and powder-coated for enhanced durability and weather resistance

- Nozzles: Stainless steel with high-pressure water for efficient, thorough cleaning

- Proportioning Pump: German-made for consistent detergent use and optimal performance

- Motor: Italian-made motor for powerful and long-lasting operation

- Automation: Optional unmanned system for hands-free operation

- Cold-Weather Compatibility: Optional intelligent low-temperature start-stop system for operation below 4°C

- Safety Features: Built-in safety measures to ensure smooth operation and prevent overuse

Our Car Wash Machine Advantages:

Different brush types can be combined, to satisfy various requirements.

Meet the needs of various scales.

Extend life and reduce corrosion.

Reduce costs and improve efficiency.

Obvious cleaning effect.

Makes the lotion proportioning more accurate and reasonable.

Makes the machine’s performance more stable and prolongs the service life.

Protect equipment, and avoid damage to the machine in a low-temperature environment.